TU Bergakademie Freiberg provides our society with the basis for an environmentally compatible supply of resources. The university has cooperative relationships with industry representatives on the regional and national level as well as with international businesses. It focuses on a sustainable material and energy economy in research and education.

➞ About the programme

➞ Programme structure

➞ Partner universities

Individualized study environment, studying in small groups

Highly practice oriented programmes – research intensive

Active campus life, all facilities within easy reach

Doctoral studies may be granted

State of the art facilities, new laboratories and studios

About the programme

The programme is designed after the concept “from construction to processing”. The discipline specific programme builds on the required knowledge acquired in mathematical scientific and engineering education that will be complemented with business and ecological aspects. The programme is oriented on the modern development of metallic materials technology and examines aspects of process design, quality control and special processes.

The programme has three sprecialisations with TU Bergakademie Freiberg

- Foundry Technology

- Forming Technology

- Steelmaking

Being a Master in MMT means to handle metallic materials in any state (liquid, fluid, solid), to work with constructors in the area of Simultaneous Engineering, to master resource conserving manufacturing technologies and to lead employees. Focus points of MMT are in any type of metal production and processing.

Students receive a national and international accepted master's degree, which is highly noted for future employers in the industry.

The German foundry and formers industry is supplier for:

- Mechanical engineering and vehicle manufacturing

- Architecture and construction industry

- Rail industry

- Shipbuilding industry

- Energy technology

- Electronic engineering

- Aerospace industry

- Healthcare sector

- The whole casting production counts for approximately six million tons per year whereof 25 % go into export

- Highly specialized engineers desperately wanted by the industry

- Annual graduate number less than the yearly industry demand

- MMT engineers especially work in the areas of:

- Material development

- Product development

- Process development

- Operations management

- Simulation of casting specific processes

- Quality Management

1 Lion monument, © Freiberg TU Bergakademie Freiberg

2 Campus TU Bergakademie Freiberg, © TU Bergakademie Freiberg

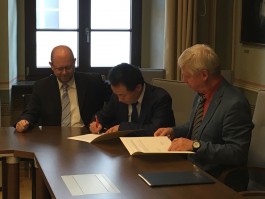

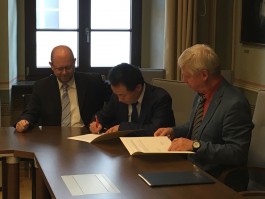

3-5 Start partner program MMT TUBAF/CZU, © Christiane Naumann

6-7 Students Freiberg, © TU Bergakademie Freiberg

Programme structure

The programme is designed after the concept “from construction to processing”. In a practice oriented programme graduates can have a seamless transition into their career in the fields of foundry industry, mechanical engineering, supplier industry, research and university institutions.

This discipline specific programme builds on the required knowledge acquired in mathematical scientific and engineering education that will be complemented with business and ecological aspects. Up to date highly productive casting processes and materials are in focus of this program.

The programme has a 3-semester duration and provides 90 Credits.

Core Programme modules are:

- Fundamentals of plastic deformation

- Materials science

- Melting technology in foundries

- Experimental methods

- Technology of iron and steel

- Metallic materials

- Thermodynamics of materials

- Master thesis

Partner universities

→ China

Dragon Horse Chinese & Foreign Entrepreneurs Service Co. Ltd. Beijing

Mrs. Li Lifang

Changzhou University

Xihua University

More information about the MMT Master Metallic Material Technology here.

TU Bergakademie Freiberg provides our society with the basis for an environmentally compatible supply of resources. The university has cooperative relationships with industry representatives on the regional and national level as well as with international businesses. It focuses on a sustainable material and energy economy in research and education.

➞ About the programme

➞ Programme structure

➞ Partner universities

Individualized study environment, studying in small groups

Highly practice oriented programmes – research intensive

Active campus life, all facilities within easy reach

Doctoral studies may be granted

State of the art facilities, new laboratories and studios

About the programme

The programme is designed after the concept “from construction to processing”. The discipline specific programme builds on the required knowledge acquired in mathematical scientific and engineering education that will be complemented with business and ecological aspects. The programme is oriented on the modern development of metallic materials technology and examines aspects of process design, quality control and special processes.

The programme has three sprecialisations with TU Bergakademie Freiberg

- Foundry Technology

- Forming Technology

- Steelmaking

Being a Master in MMT means to handle metallic materials in any state (liquid, fluid, solid), to work with constructors in the area of Simultaneous Engineering, to master resource conserving manufacturing technologies and to lead employees. Focus points of MMT are in any type of metal production and processing.

Students receive a national and international accepted master's degree, which is highly noted for future employers in the industry.

The German foundry and formers industry is supplier for:

- Mechanical engineering and vehicle manufacturing

- Architecture and construction industry

- Rail industry

- Shipbuilding industry

- Energy technology

- Electronic engineering

- Aerospace industry

- Healthcare sector

- The whole casting production counts for approximately six million tons per year whereof 25 % go into export

- Highly specialized engineers desperately wanted by the industry

- Annual graduate number less than the yearly industry demand

- MMT engineers especially work in the areas of:

- Material development

- Product development

- Process development

- Operations management

- Simulation of casting specific processes

- Quality Management

1 Lion monument, © Freiberg TU Bergakademie Freiberg

2 Campus TU Bergakademie Freiberg, © TU Bergakademie Freiberg

3-5 Start partner program MMT TUBAF/CZU, © Christiane Naumann

6-7 Students Freiberg, © TU Bergakademie Freiberg

Programme structure

The programme is designed after the concept “from construction to processing”. In a practice oriented programme graduates can have a seamless transition into their career in the fields of foundry industry, mechanical engineering, supplier industry, research and university institutions.

This discipline specific programme builds on the required knowledge acquired in mathematical scientific and engineering education that will be complemented with business and ecological aspects. Up to date highly productive casting processes and materials are in focus of this program.

The programme has a 3-semester duration and provides 90 Credits.

Core Programme modules are:

- Fundamentals of plastic deformation

- Materials science

- Melting technology in foundries

- Experimental methods

- Technology of iron and steel

- Metallic materials

- Thermodynamics of materials

- Master thesis

Partner universities

→ China

Dragon Horse Chinese & Foreign Entrepreneurs Service Co. Ltd. Beijing

Mrs. Li Lifang

Changzhou University

Xihua University

More information about the MMT Master Metallic Material Technology here.